Pneumatic butterfly valve cylinder principle

Pneumatic butterfly valve can run smoothly, the key lies in the aspect of the pneumatic actuator, also known as the pneumatic head, pneumatic head by the air intake cylinder for power, with the valve stem valve plate movement.

Operating principle of pneumatic actuator (principle of pneumatic butterfly valve cylinder)

AT series pneumatic actuators are double piston rack and gear rotating structure design, divided into double action and single action (spring return), suitable for outdoor or indoor various non-corrosive or corrosive environment.

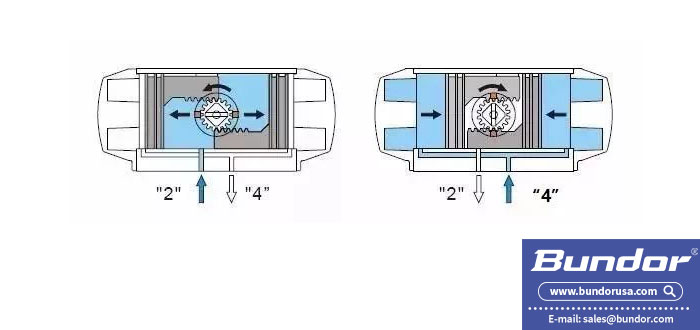

Schematic diagram of double-acting pneumatic actuator

Double-acting pneumatic head: ventilation open, ventilation closed.Double-acting pneumatic actuators are often seen in piston cylinders when the air source is lost.The valve can be in the position (FL) state.

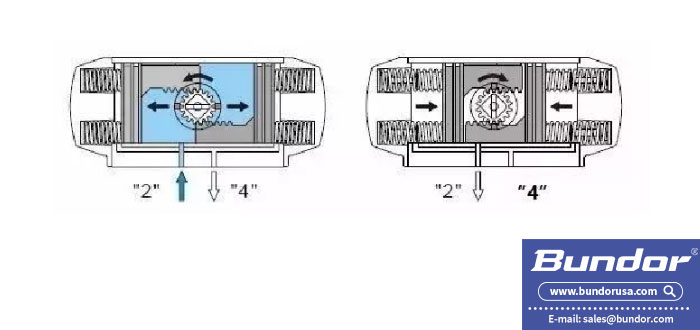

Schematic diagram of single-acting pneumatic actuator

Double-acting pneumatic head: ventilation open, ventilation closed.Double-acting pneumatic actuators are often seen in piston cylinders when the air source is lost.The valve can be in the position (FL) state.

Schematic diagram of single-acting pneumatic actuator

When the air source pressure from the air port (2) into the middle chamber between the two pistons of the cylinder, make the two pistons separate and move toward the two ends of the cylinder, forcing the springs at both ends to compress, the air at both ends of the air cavity through the air port (4) exhaust, at the same time make the two pistons rack synchronously drive the output shaft (gear) to rotate counterclockwise.After the air source pressure changes direction through the solenoid valve, the two pistons of the cylinder move in the middle direction under the spring force, and the air in the middle air chamber is discharged from the air port (2), and the rack of the two pistons synchronously drives the output shaft (gear) to rotate clockwise.If the piston is installed in the opposite direction, the output shaft will rotate in the opposite direction when the spring is returned.

Single acting pneumatic head with spring return:

Normally closed type (gas open type), normally open type (gas closed type)

Normally closed type ventilation open, closed.Normally open type ventilation closed, break open.

简体中文

简体中文 Русский

Русский Español

Español Bundor - Butterfly, Gate, Check, Ball, Globe Valve Manufacturer, Supplier & Distributor

Bundor - Butterfly, Gate, Check, Ball, Globe Valve Manufacturer, Supplier & Distributor