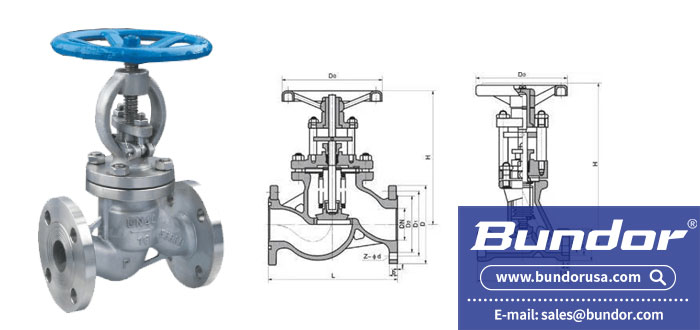

Globe valve "low in high" and "high in low out" which good?

Why are globe valves designed to be low and high?

Globe valves are designed for low inlet and high flow resistance to save effort when opening the valve.At the same time when the valve is closed, the cushion between the valve shell and the valve cover and the packing around the valve stem is not stressed, will not be affected by medium pressure and temperature for a long time to extend the service life, reduce the chance of leakage.In addition, the valve can be closed in the state of replacement or add packing, easy to repair.

Many people think that the globe valve is low and high, but it is not.In general, globe valves are low in and high out. However, in some special cases, globe valves are high in and low out:

1. High pressure globe valve with diameter greater than 100mm

Due to the poor sealing performance of large diameter valves, this method of globe valves in the closed state, medium pressure on the disc above to increase the valve sealing.

2. Two globe valves in series on the bypass pipeline. The second globe valve requires "high in and low out".

In order to ensure the strictness of the valve within a maintenance period, the valve that often opens and closes is required to be equipped with two stop valves in series.For the bypass system, the functions of this bypass installation are:

(1) Balance the front and back pressure of the main pipe valve, make it convenient and labor-saving to open, and reduce the wear of the main pipe valve;

(2) Small and medium flow heating pipe in the starting process;

(3) On the main water supply pipeline, control the water supply flow to control the boiler pressure boost speed for the boiler hydraulic test.The bypass globe valves are primary and secondary valves according to the flow direction of the medium. The primary and secondary valves are closed during the normal operation of the unit, and both of them are in direct contact with the medium.The secondary valve requires a "high in and low out" installation direction to prevent the padding between the secondary valve housing and bonnet and the packing around the stem from being subjected to medium and temperature for a long time, and the valve packing can be replaced during operation.

3. Boiler exhaust and vent stop valve

Boiler exhaust and vent globe valves are only used in the process of boiler starting water, with small opening and closing frequency, but often due to loose sealing and resulting in the loss of working medium. Therefore, some power plants install such globe valves in the direction of "high in and low out" in order to improve the tightness.

4. Electromagnetic quick-break valve

The solenoid quick-break valve is designed to shut down quickly and cut off fuel supply quickly.The structure of the solenoid quick break valve is similar to that of the globe valve. If the solenoid quick break valve is also a working medium that enters from the lower part and flows out from the upper part, the force of fuel acting on the lower part of the solenoid quick break valve disc is very large, and the weight of the solenoid quick break valve is far less than it.Therefore, if the working medium enters the quick-break valve from the lower part, the torque produced by the heavy hammer is less than the torque produced by the fuel pressure. When the quick-break valve operates, the fuel cannot be cut off, thus failing to achieve the expected purpose.If the working medium from the upper part of the quick break valve, because the quick break valve once the action, the pressure after the valve quickly reduced, the force of the fuel action on the lower part of the valve disc quickly dropped to zero, and the force of the fuel action on the valve disc and the weight of the hammer, lever formed by the force.

It is difficult to close the valve when using low inlet and high pressure under large diameter and high pressure. If using low inlet and high pressure under large diameter and high pressure, the valve stem is prone to deformation and bending under water pressure for a long time, affecting the safety and sealing of the valve;Choose high low point on the stem diameter can be small, for manufacturers and users will also save some cost.

简体中文

简体中文 Русский

Русский Español

Español Bundor - Butterfly, Gate, Check, Ball, Globe Valve Manufacturer, Supplier & Distributor

Bundor - Butterfly, Gate, Check, Ball, Globe Valve Manufacturer, Supplier & Distributor