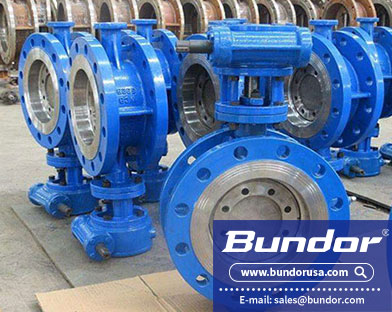

How to understand eccentric butterfly valve

Posted by Bundor valve

Eccentric butterfly valve is divided into single eccentric butterfly valve, double eccentric butterfly valve, triple eccentric butterfly valve.

Single eccentric butterfly valve is now rarely used, its appearance is to solve the problem of concentric butterfly valve disc and seat extrusion, single eccentric butterfly valve structure features for the stem axis deviated from the disc center, so that the disc upper and lower end is no longer a rotary axis, disperse, reduce the butterfly plate upper and lower end and seat excessive extrusion.But because the single eccentric structure in the valve in the entire switching process of the butterfly plate and the seat of the scraping phenomenon does not disappear, in the application range and concentric butterfly valve is similar, so the use of little.

Double eccentric butterfly valves are characterized by relative eccentricity between the center of the valve shaft and the center line of the valve body and the sealing center line of the valve plate.The double eccentric structure makes the valve cricket surface and sealing surface quickly separate and contact when the valve is on and off, reduces the friction torque force between the valve plate and sealing surface, reduces the wear and improves the life of the valve.However, the valve plate in the switch 0 ~ 10° range and the valve plate axial sealing surface near the upper and lower ends can not be separated, is still in the sliding friction state, at this time the torque is large, easy to cause the scratch, bite, thus can cause sealing leakage phenomenon.From the structure analysis, the double eccentricity belongs to the single direction butterfly valve.

Triple eccentric butterfly valve is on the basis of double eccentricity, increase the valve cone sealing base center line deviation to the center line of the valve body, that is, from the positive conical seal to oblique conical seal.After the third eccentricity, the sealing section of the butterfly plate is oval.The structure makes the minimum pressure Angle of 360° circular sealing surface greater than the friction Angle, so as to eliminate local mutual friction and jamming phenomenon, realize the sealing surface separation and contact of valve plate at the moment of switch, greatly reduce the friction torque force when the valve is opened and closed, solve the defects of double eccentric butterfly valve sealing structure, and extend the service life of valve.

Single eccentric butterfly valve is now rarely used, its appearance is to solve the problem of concentric butterfly valve disc and seat extrusion, single eccentric butterfly valve structure features for the stem axis deviated from the disc center, so that the disc upper and lower end is no longer a rotary axis, disperse, reduce the butterfly plate upper and lower end and seat excessive extrusion.But because the single eccentric structure in the valve in the entire switching process of the butterfly plate and the seat of the scraping phenomenon does not disappear, in the application range and concentric butterfly valve is similar, so the use of little.

Double eccentric butterfly valves are characterized by relative eccentricity between the center of the valve shaft and the center line of the valve body and the sealing center line of the valve plate.The double eccentric structure makes the valve cricket surface and sealing surface quickly separate and contact when the valve is on and off, reduces the friction torque force between the valve plate and sealing surface, reduces the wear and improves the life of the valve.However, the valve plate in the switch 0 ~ 10° range and the valve plate axial sealing surface near the upper and lower ends can not be separated, is still in the sliding friction state, at this time the torque is large, easy to cause the scratch, bite, thus can cause sealing leakage phenomenon.From the structure analysis, the double eccentricity belongs to the single direction butterfly valve.

Triple eccentric butterfly valve is on the basis of double eccentricity, increase the valve cone sealing base center line deviation to the center line of the valve body, that is, from the positive conical seal to oblique conical seal.After the third eccentricity, the sealing section of the butterfly plate is oval.The structure makes the minimum pressure Angle of 360° circular sealing surface greater than the friction Angle, so as to eliminate local mutual friction and jamming phenomenon, realize the sealing surface separation and contact of valve plate at the moment of switch, greatly reduce the friction torque force when the valve is opened and closed, solve the defects of double eccentric butterfly valve sealing structure, and extend the service life of valve.

简体中文

简体中文 Русский

Русский Español

Español Bundor - Butterfly, Gate, Check, Ball, Globe Valve Manufacturer, Supplier & Distributor

Bundor - Butterfly, Gate, Check, Ball, Globe Valve Manufacturer, Supplier & Distributor