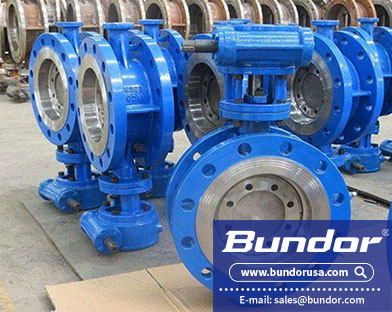

Triple eccentric butterfly valve features

Posted by Bundor valve

Today, hard seal butterfly valve has been widely used in petroleum, chemical, metallurgy, power generation and many other fields, used to cut off or control the flow medium in the pipeline system.At present, there is a more advanced, hard seal butterfly valve is triple eccentric butterfly valve, the valve body and seat is a Siamese components, on the valve seat sealing surface, welding heat resistance, corrosion resistant alloy material, and multi-layer soft fold type sealing ring is fixed on the valve plate, the design of novel, let triple eccentric butterfly valve overcomes the drawback of poor sealing performance.

Triple eccentric butterfly valve has the advantages of high temperature resistance, small friction when opening and closing, when closing, butterfly plate with the driving mechanism torque increase to compensate the sealing, greatly improve the sealing performance of hard sealing butterfly valve, prolong the service life of the valve.

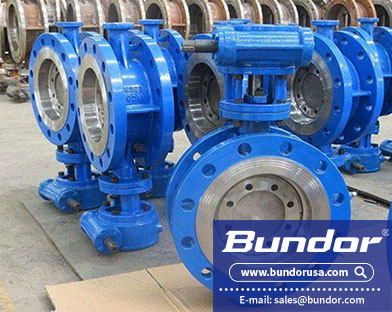

Advantages of triple eccentric butterfly valve:

1.Unique three-eccentric design enables frictionless transmission between butterfly plate and sealing surface of valve body, reducing wear and extending service life.

2.Can adapt well to low temperature, normal temperature and high temperature environment.

3. Pneumatic and electric devices can be configured according to users' needs to meet the needs of remote control and program control.

triple eccentric butterfly valve defects are:

1.The butterfly plate of hard seal butterfly valve is fixed by multiple layers of hard and soft overlapping sealing rings. When the butterfly plate is in the normally open state, the flow medium will form a positive erosion on the sealing surface, which will affect the sealing performance of the valve over time.

2.Due to the hard seal butterfly valve butterfly plate overall structure is too thick, the flow resistance is relatively large, so the valve is not suitable for the diameter below DN200.

Triple eccentric butterfly valve has the advantages of high temperature resistance, small friction when opening and closing, when closing, butterfly plate with the driving mechanism torque increase to compensate the sealing, greatly improve the sealing performance of hard sealing butterfly valve, prolong the service life of the valve.

Advantages of triple eccentric butterfly valve:

1.Unique three-eccentric design enables frictionless transmission between butterfly plate and sealing surface of valve body, reducing wear and extending service life.

2.Can adapt well to low temperature, normal temperature and high temperature environment.

3. Pneumatic and electric devices can be configured according to users' needs to meet the needs of remote control and program control.

triple eccentric butterfly valve defects are:

1.The butterfly plate of hard seal butterfly valve is fixed by multiple layers of hard and soft overlapping sealing rings. When the butterfly plate is in the normally open state, the flow medium will form a positive erosion on the sealing surface, which will affect the sealing performance of the valve over time.

2.Due to the hard seal butterfly valve butterfly plate overall structure is too thick, the flow resistance is relatively large, so the valve is not suitable for the diameter below DN200.

简体中文

简体中文 Русский

Русский Español

Español Bundor - Butterfly, Gate, Check, Ball, Globe Valve Manufacturer, Supplier & Distributor

Bundor - Butterfly, Gate, Check, Ball, Globe Valve Manufacturer, Supplier & Distributor